Next-Gen Research at Nanostratus

Find out about all the latest research happening in our R&D labs

SLIPS

Nanostratus is actively involved in the research and development of next-gen easy cleaning surfaces. A slippery liquid-infused porous surface (SLIPS) or liquid impregnated surface (LIS) is a two-layered coating solution with the first layer providing a highly textured porous surface and the second layer offering a low surface energy surface from the impregnated liquid. The first layer is designed such that the loss of lubricating liquid can be eliminated. SLIPS finds numerous applications as ultra-slip easy-clean surfaces, anti-fouling, anti-icing, food waste prevention, medical devices, and protective layer for surface degradation prevention. SLIPS offers several advantages compared to the traditional lotus-based super(de)wetting coatings. The superhydrophobic coatings once abraded lose their waterproofing properties, which we have addressed by developing an ultra-robust coating, DuraSemper™, capable of withstanding 500+ cycles of harsh rotary abrasive cycles. Comparatively, SLIPS have the capability of self-repair when damaged due to infused liquid flowing to the damaged regions. In addition, SLIPS can be made highly transparent due to a smooth topcoat in contrast to a rough topcoat for super(de)wetting coatings which lead to light scattering and significant haze issues. We addressed the transmission and haze problem of super(de)wetting coatings via our DuraVitrum™ product range, which is still under development. SLIPS can also offer very low sliding angles for both high and low surface tension liquids. Interested in knowing more about our research in SLIPS: Contact Us!

Anti-fogging Coatings

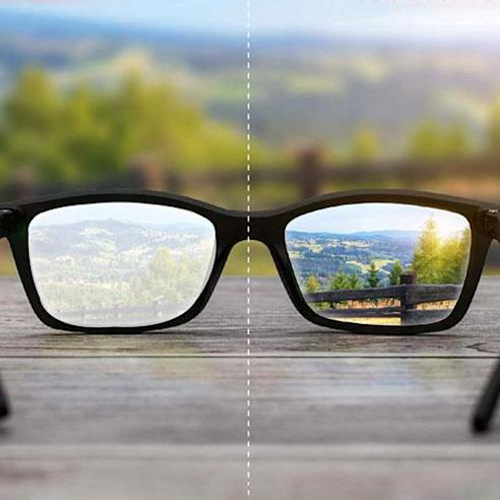

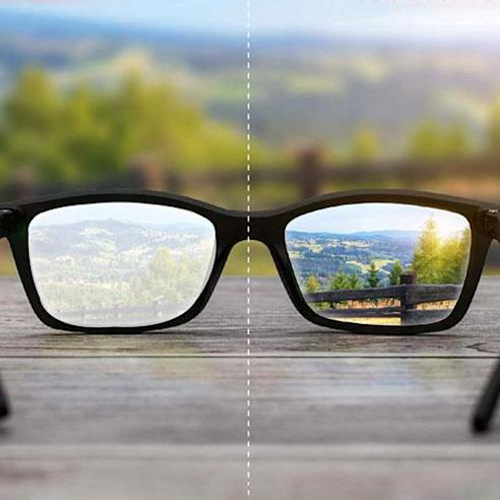

Nanostratus is also actively engaged in the research and development of next-gen antifogging coatings. Fogging is the condensation of tiny water droplets on a surface which can then act as nucleation sites for further growth. Coatings being developed will apply to any surface including transparent, translucent, and opaque objects, and would be ideal for optical applications such as ophthalmic lenses, goggles, camera lenses and sensors, mirrors, windowpanes, automotive windshields, and the likes. The technology works in complete contrast to super(de)wetting coatings where water is made to repel from the surface. For anti-fogging coatings, the water droplets wet the surface completely forming a super-wetting state thereby providing complete transparency while eliminating fogging. The technology was first researched by NASA improving the spacesuits of their astronauts and we are bringing this technology to consumer homes. Interested in knowing more about our research in anti-fogging coatings: Contact Us!

SLIPS

Nanostratus is actively involved in the research and development of next-gen easy cleaning surfaces. A slippery liquid-infused porous surface (SLIPS) or liquid impregnated surface (LIS) is a two-layered coating solution with the first layer providing a highly textured porous surface and the second layer offering a low surface energy surface from the impregnated liquid. The first layer is designed such that the loss of lubricating liquid can be eliminated. SLIPS finds numerous applications as ultra-slip easy-clean surfaces, anti-fouling, anti-icing, food waste prevention, medical devices, and protective layer for surface degradation prevention. SLIPS offers several advantages compared to the traditional lotus-based super(de)wetting coatings. The superhydrophobic coatings once abraded lose their waterproofing properties, which we have addressed by developing an ultra-robust coating, DuraSemper™, capable of withstanding 500+ cycles of harsh rotary abrasive cycles. Comparatively, SLIPS have the capability of self-repair when damaged due to infused liquid flowing to the damaged regions. In addition, SLIPS can be made highly transparent due to a smooth topcoat in contrast to a rough topcoat for super(de)wetting coatings which lead to light scattering and significant haze issues. We addressed the transmission and haze problem of super(de)wetting coatings via our DuraVitrum™ product range, which is still under development. SLIPS can also offer very low sliding angles for both high and low surface tension liquids. Interested in knowing more about our research in SLIPS: Contact Us!

Anti-fogging Coatings

Nanostratus is also actively engaged in the research and development of next-gen antifogging coatings. Fogging is the condensation of tiny water droplets on a surface which can then act as nucleation sites for further growth. Coatings being developed will apply to any surface including transparent, translucent, and opaque objects, and would be ideal for optical applications such as ophthalmic lenses, goggles, camera lenses and sensors, mirrors, windowpanes, automotive windshields, and the likes. The technology works in complete contrast to super(de)wetting coatings where water is made to repel from the surface. For anti-fogging coatings, the water droplets wet the surface completely forming a super-wetting state thereby providing complete transparency while eliminating fogging. The technology was first researched by NASA improving the spacesuits of their astronauts and we are bringing this technology to consumer homes. Interested in knowing more about our research in anti-fogging coatings: Contact Us!